Cooperation between AMBARtec AG and Rouge H2 Engineering AG – solutions for climate-neutral steelworks

Dresden, 10 July 2025 – AMBARtec and Rouge H2 Engineering are set to collaborate closely in the future to bring the chemical looping hydrogen process to market maturity. This process can be used to produce clean hydrogen and concentrated carbon dioxide from blast furnace gas and other steel mill gases. It is based on the steam-iron process, which can be used to produce high-purity hydrogen by reducing and oxidising iron oxide or iron nuggets. The highly concentrated CO₂ obtained can be effectively utilised in CCU or CCS processes.

The Chemical Looping Hydrogen process

This two-stage process uses iron oxide (FeOx) to convert carbon-containing gas mixtures into hydrogen (H₂) and carbon dioxide (CO₂). ‘Our collaboration aims to optimise the process for blast furnace gases and implement it in steelworks,’ reports Uwe Pahl, Chief Technology Officer at AMBARtec. Blast furnace gas, coke oven gas and converter gas can thus be processed to generate high-quality hydrogen. The high-purity carbon dioxide produced during this process can be utilised as a material (CCU) or stored (CCS). The precondition for this green transformation of the steel industry is that the CCS Act, which is currently being revised, must authorise the storage of CO2 from the steel industry. 'This gives the steel industry the chance to make its production more climate-friendly without having to invest heavily in converting the entire process chain. This will ensure that steel production in Europe remains competitive despite the stringent climate protection requirements,’ emphasises Uwe Pahl

Partner from the steel industry

The EU project H2Loop* provides the framework for this cooperation. ‘We are combining our expertise in iron oxide nuggets and our experience in plant operation with the knowledge of our colleagues at Rouge H2 Engineering in the processing of residual gases,’ explains Matthias Rudloff, CEO of AMBARtec.

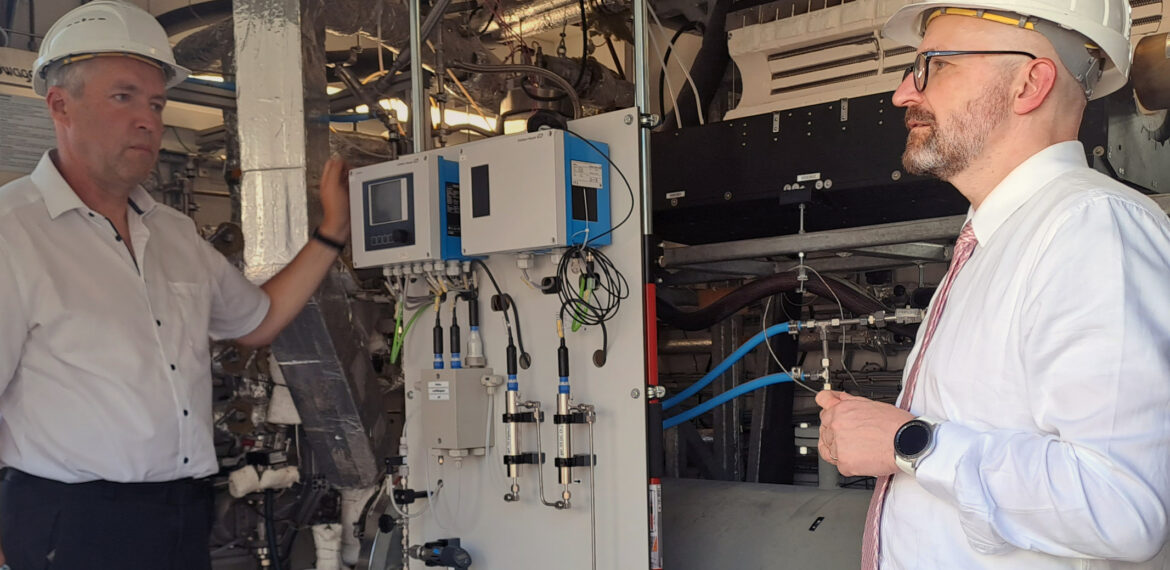

Picture above: Testing of the chemical looping hydrogen reactor at Rouge H2 Engineering.

Picture below: Test plant for the chemical looping hydrogen process at Rouge H2 Engineering AG.

In addition to Rouge H2 Engineering, the project also involves two partners from the steel industry. ‘With their input, we will align the process and associated plant technology with real conditions in steelworks from the beginning and demonstrate this at our partner's premises,’ emphasises Matthias Rudloff. ‘We look forward to receiving constructive support from other steel companies.’

The role of iron oxide nuggets

Blast furnace gases contain relevant quantities of carbon monoxide (CO) and hydrogen. If these gases are added to iron oxide nuggets under the right conditions, the iron oxide is reduced and carbon dioxide and steam are released.

FeOx + CO/H₂ -> FeO + CO₂/H₂O

The carbon dioxide is separated and made available for utilisation or storage, for example via CCS.

In the second step, the reduced iron oxide nuggets are re-oxidised using steam.

This process produces high-purity hydrogen, which can be used as both a material and an energy source.

Pressekontakt:

Dr. Ines Bilas

AMBARtec AG

Head of Marketing and Communication

Phone: +49 172 234 11 00

E-Mail: ines.bilas@ambartec.de

Website: www.ambartec.de