HyCS®-Technology: simple and effective

Reduction and Oxidation

At its core, HyCS® technology consists of the reduction and oxidation of iron (Fe): During storage loading, the iron oxide is reduced by the added hydrogen. Steam is released and can be used again in electrolysis. During discharge, steam is fed at the point of use, which can also come from the exhaust gas of a regeneration unit. This oxidizes the Fe and H₂ is provided.

First commercial units available

Our hydrogen compact storage technology (HyCS®) has been demonstrated and proven since early 2022. First commercial units are already available from 2023. Our 20-foot standard containers will be available by 2024. Solutions for large-scale applications are being designed on client’s request.

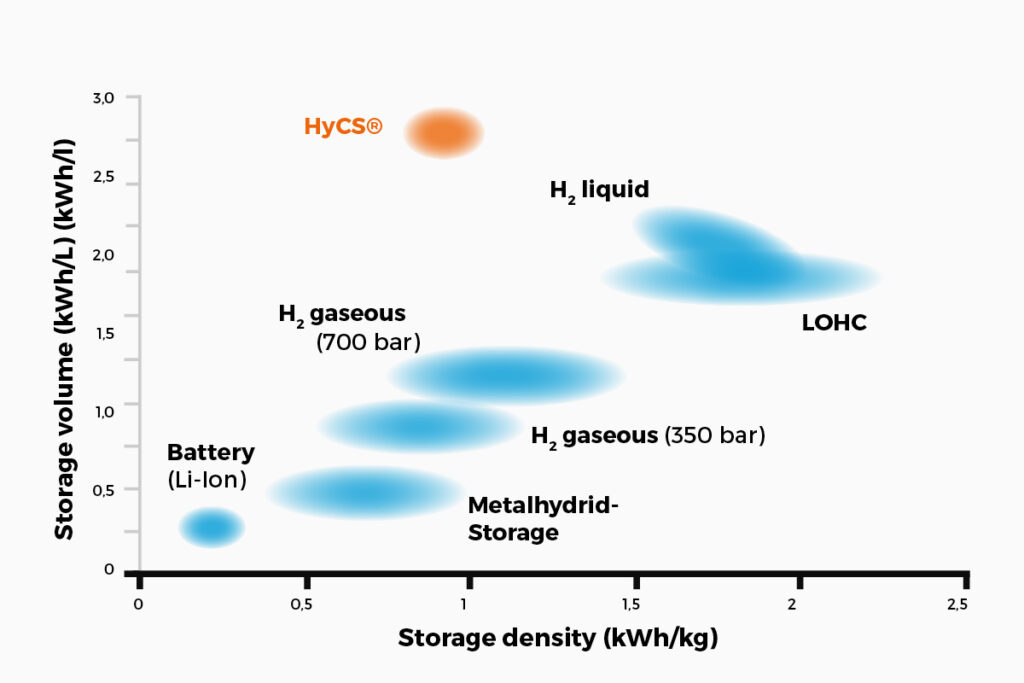

Highest storage density

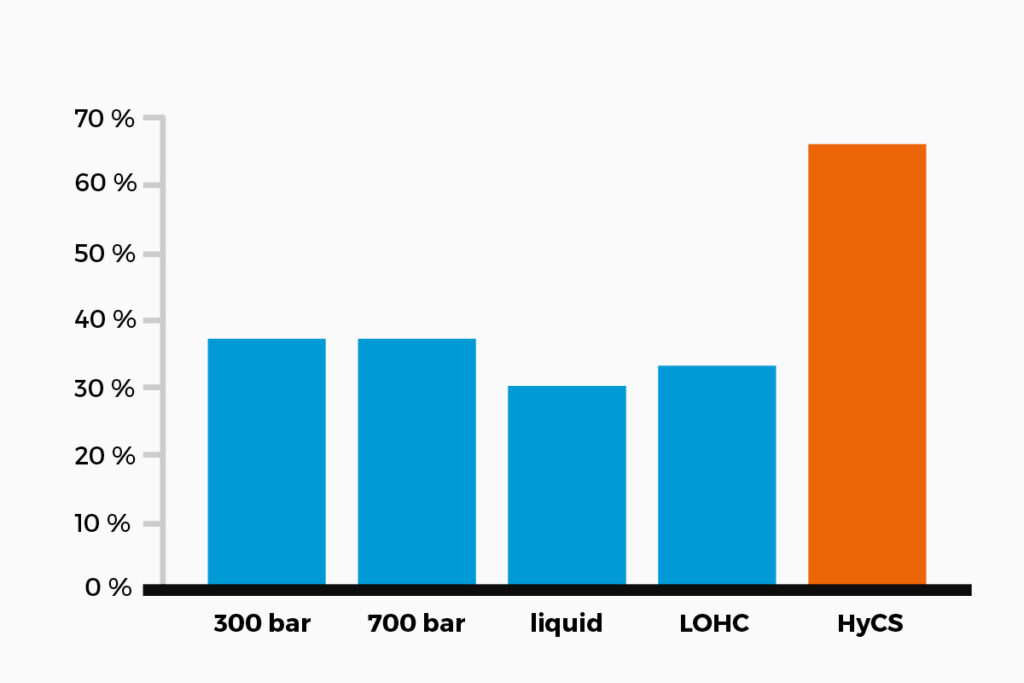

Best efficiency

Smart integration, especially with steam driven electrolysis (SOEC) and SOFC fuel cells, results in long-term power storage efficiencies of up to 100% higher than with alternative systems. HyCS® technology thus reduces H₂ generation and storage costs.

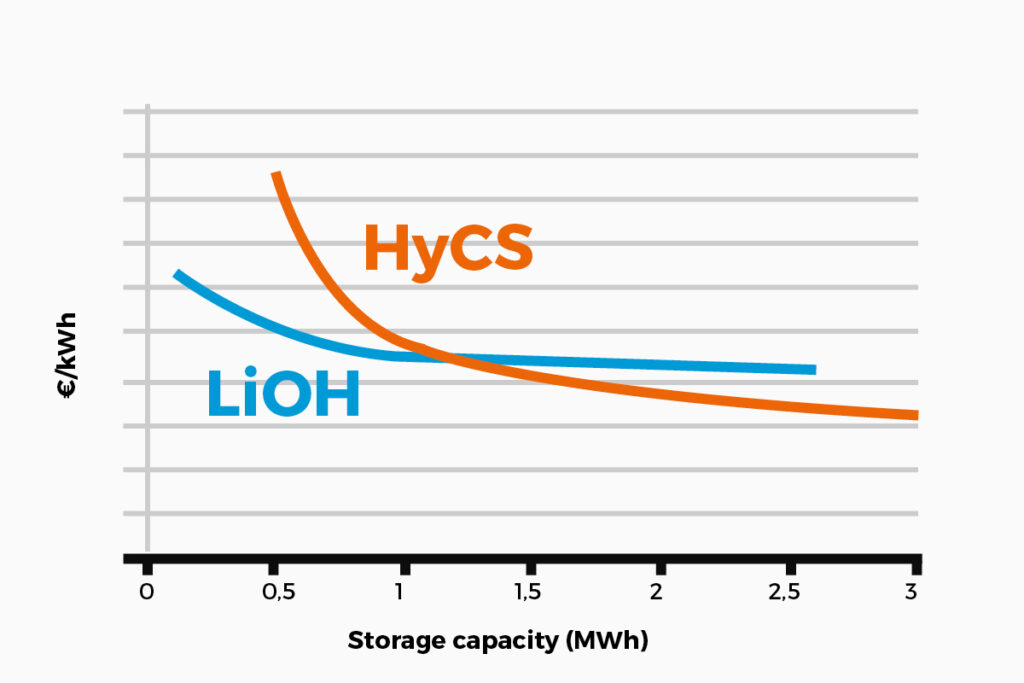

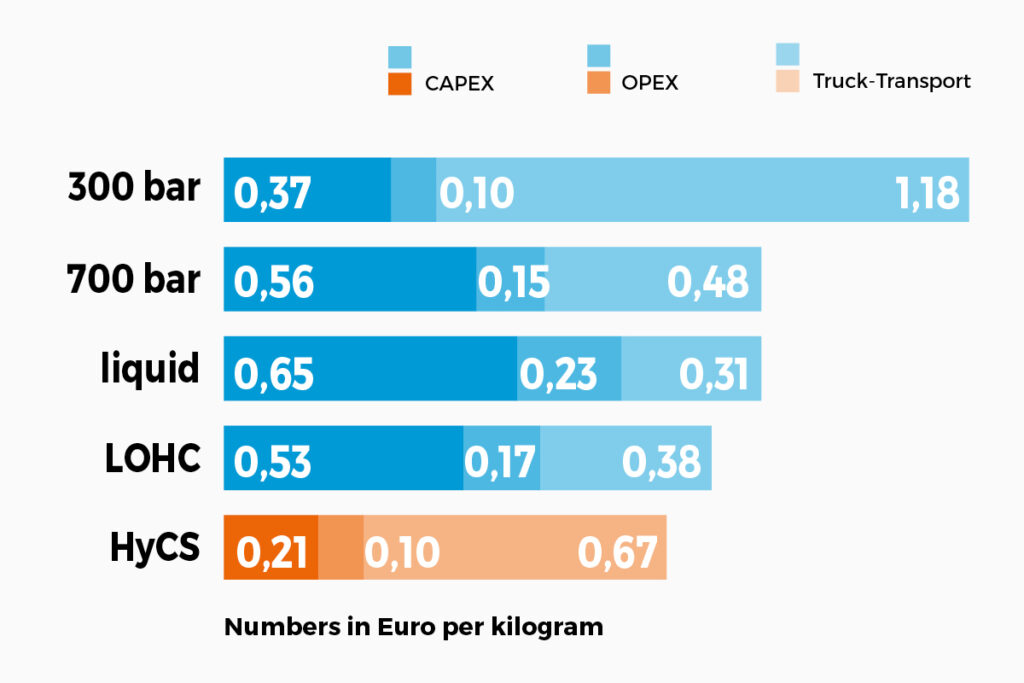

Reduced transport costs

HyCS® technology means:• Halving the space requirement for H₂ storage

• 2 x as much H₂/truck as in bundles of bottles

• Reduction of H₂ generation and storage costs